Driving the Future: How Private Blockchains Are Revolutionizing Automotive Logistics

In an industry where seconds count and transparency is gold, a quiet revolution is reshaping the automotive supply chain

"We're witnessing a paradigm shift," says Dr. Markus Schmidt, Chief Digital Officer at Continental AG. "Private blockchains are doing for automotive logistics what the assembly line did for manufacturing—revolutionizing efficiency and creating new possibilities we're only beginning to grasp."

The numbers paint a compelling picture. A 2023 Deloitte study found that automotive companies implementing private blockchain solutions saw an average 30% reduction in supply chain disruptions and a 25% decrease in recall-related costs. For an industry where a single day of production disruption can cost millions, these efficiencies translate to a significant competitive edge.

Unlocking the Power of Private Blockchains

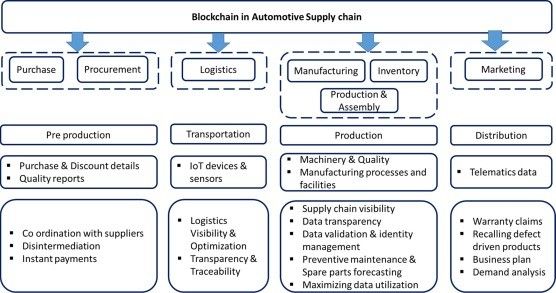

At its core, a private blockchain is a decentralized, tamper-proof ledger accessible only to authorized participants. Unlike public blockchains used for cryptocurrencies, private blockchains offer the benefits of the technology—immutability, transparency, and real-time updates—while maintaining the control and privacy crucial for sensitive business operations.

"Think of it as a digital handshake that's impossible to fake," explains Sarah Chen, blockchain specialist at IBM. "Every transaction, every movement of parts or vehicles, is recorded and verified by multiple parties in real-time. It's trust, codified."

This trust is proving transformative. BMW Group, an early adopter of blockchain in its supply chain, reported a 50% reduction in administrative costs related to supplier onboarding and a 35% improvement in parts traceability since implementing its PartChain platform in 2020.

The Interoperability Imperative

While individual blockchain initiatives show promise, the true potential lies in interoperability—the ability for different blockchain networks to communicate and share data seamlessly. It's here that the automotive industry is breaking new ground.

The Mobility Open Blockchain Initiative (MOBI), a consortium of major automakers including Ford, GM, and BMW, is spearheading efforts to create industry-wide standards for blockchain implementation. Their Vehicle Identity (VID) standard, launched in 2021, creates a "birth certificate" for each vehicle, tracking its entire lifecycle from production to scrapyard.

"Interoperability is the key to unlocking blockchain's full potential," says MOBI founder Chris Ballinger. "Without it, we risk creating a new generation of digital silos. With it, we're laying the foundation for a truly integrated, efficient global supply chain."

Real-World Impact

The benefits of this blockchain revolution extend far beyond abstract efficiencies. Consider the case of Volkswagen, which implemented a blockchain-based system to track cobalt used in electric vehicle batteries. By providing an immutable record of the mineral's journey from mine to manufacturing plant, VW not only improved supply chain visibility but also addressed growing consumer concerns about ethical sourcing.

Similarly, Toyota's track and trace blockchain pilot with its European suppliers led to a 20% reduction in lead times for critical parts and a 30% decrease in quality-related issues. "We can now pinpoint the exact location and status of any component in our supply chain within seconds," notes Alisa Suzuki, Toyota's Head of Supply Chain Innovation. "It's transforming how we manage inventory, plan production, and respond to disruptions."

Challenges and Opportunities

Despite its promise, the road to widespread blockchain adoption in automotive logistics isn't without bumps. Data standardization remains a significant hurdle, with many suppliers still struggling to digitize their operations fully. There's also the challenge of scaling blockchain networks to handle the immense volume of transactions in global automotive supply chains.

"The technology is ready, but the ecosystem isn't quite there yet," cautions Dr. Schmidt. "We need greater collaboration across the industry, from tier-3 suppliers to dealerships, to realize the full potential of blockchain interoperability."

For executives, the message is clear: the blockchain train is leaving the station, and the cost of not being on board is growing. Early movers are already reaping significant benefits in efficiency, traceability, and risk mitigation.

The Intelligent, Integrated Supply Chain

As we peer into the future, the contours of a truly intelligent, blockchain-powered automotive supply chain are emerging. Imagine a world where vehicles automatically order their own replacement parts based on predictive maintenance data, or where customs clearance happens in seconds thanks to blockchain-verified shipping records.

This isn't idle speculation. Startups like CargoX are already using blockchain to digitize bills of lading, cutting document processing time from days to minutes. Meanwhile, companies like DHL and Accenture are exploring blockchain's potential for automating payments and settlements in logistics.

For automotive executives, the imperative is clear: start building blockchain capabilities now. This means investing in pilot projects, upskilling teams, and actively participating in industry-wide standardization efforts.

"The companies that will lead in the coming decade are those that view their supply chains not as cost centers, but as strategic assets powered by blockchain," predicts Ballinger.

As private blockchains and interoperability initiatives continue to reshape automotive logistics, one thing is certain: the supply chains of tomorrow will be more transparent, efficient, and responsive than ever before. For leaders willing to embrace this blockchain-driven future, the road ahead is full of opportunity. The question isn't whether to adopt blockchain in logistics, but how quickly you can shift into high gear.